Tableting

Another major technology in our portfolio is shaping powders by means of pressing them. Exacer has multiple tableting lines available.

At Exacer we have a team of experienced tableting experts to tackle even the most challenging requests and for setting up a cost efficient production.

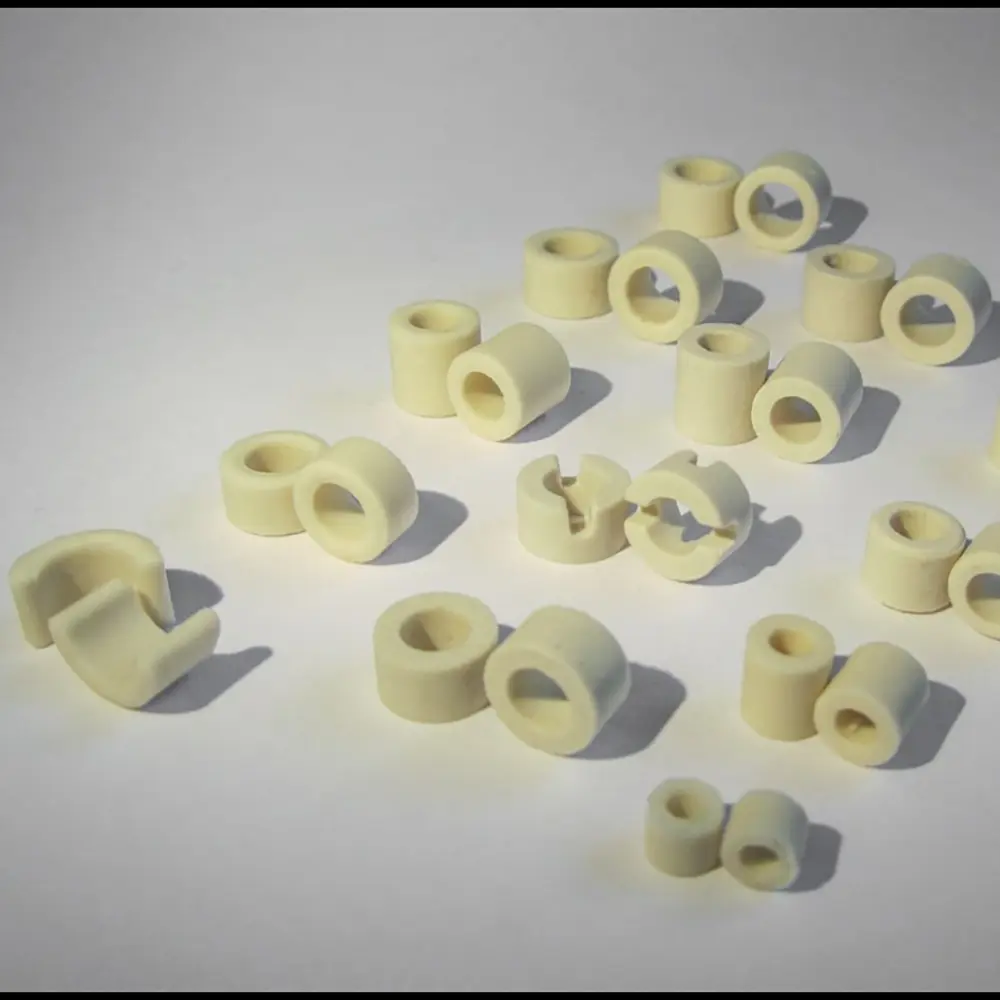

We can do various shapes, such as straight cylinders, rings, structures with rounded faces, slots or 3D-edges, multi-hole tablets, or even spheres. The tablets can be as tiny as 1.5×1.5 mm or have a diameter up to 35 mm.

Supplementary unit operations such as powder mixing and pre-compaction are available.

Besides inert materials, such as alumina or steatite, Exacer can also process catalyst powders with active ingredients. For processing hazardous materials, there is a separate ‘black room’ area, where a tableting machine can be run under safe conditions and a controlled atmosphere.

Please do not hesitate to ask us about our commercially sold carrier portfolio or options for toll manufacturing with our tableting machines!