Transferring Italian core expertise to modern products for the chemical industry

Extrusion

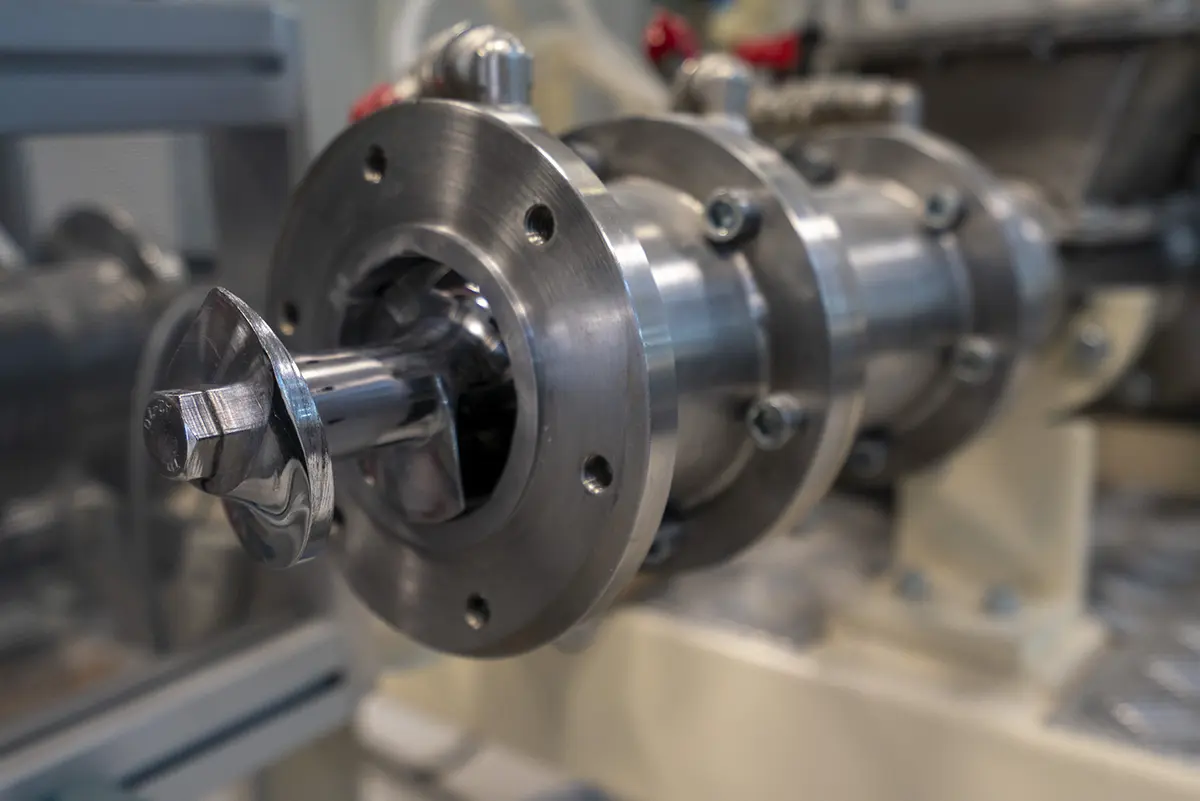

One of the predominant technologies for shaping in our portfolio is extrusion. Exacer has many different extrusion technologies at hand which are employed in combination with an appropriate mixing technique that is best for the specific product.

While extrusion is generally a good option for massive and cost-effective bulk production of several hundred tons per year, there are also small niche products with only a few tons per campaign which make in particular use of the high flexibility of this technology.

At Exacer we have the following capabilities

- Continuous and discontinuous extrusion

- Optional extrusion under vacuum

- Highly automated lines with integrated mixing/drying/calcination for an efficient production

- Advanced cutting technology

- Experience with requests on challenging shapes (e.g., multi-hole structures) or materials (e.g. α-alumina powder processing)

- Not just carriers, also extrusion of powders, containing active metals

- Ability for quick capacity expansions in order to keep pace with the marketing efforts of our customers

- Small units for producing scalable pilot quantities of a few kilograms

Please do not hesitate to ask us about our commercially sold carrier portfolio or options for toll manufacturing on our extrusion lines!